Firstly, the company conducts product development and design stages. This stage includes market research, product planning, and the production of design drawings. The R&D team determines product functionality and performance requirements through repeated communication and improvement with customers. Once the design scheme is determined, it enters the next stage.

The second stage is material procurement and preparation. The company needs to purchase various materials and components suitable for producing engraving machines, including metal sheets, electronic components, motion control systems, etc. The selection and cooperation of suppliers are also important aspects of this stage. All materials and components need to meet the quality and performance standards of the product.

Thirdly, it is the construction and preparation of the production line. The company needs to plan production line layout and process flow based on design requirements and production capacity requirements. This includes adjusting and installing equipment, writing production processes and documents, training workers, etc. The construction of production lines is an important link to ensure production efficiency and stable quality.

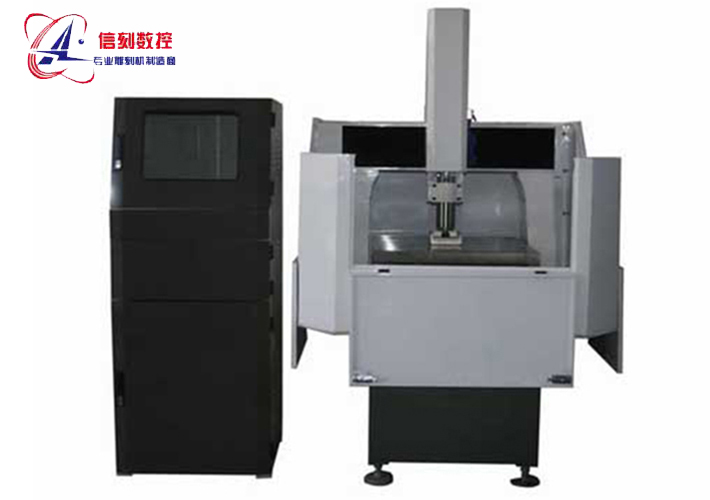

Fourthly, it is the production and manufacturing process. Once the production line is completed, the company will officially start producing carving machines. Each production unit has its own tasks and process flow, from assembling components to testing and debugging, and then to whole machine debugging and packaging for shipment. The production process needs to ensure product quality and delivery time.

Finally, it is the after-sales service and quality monitoring stage. The company conducts quality testing on the Engraving machines produced and provides after-sales service. Customer feedback and feedback are collected and processed in a timely manner to continuously improve product and service quality. At the same time, the quality monitoring team also needs to monitor and improve the production process.

The above is the basic process and main links of the company's production of carving machines. As for the length of the cycle, it depends on multiple factors, including product complexity, production line efficiency, material supply stability, order volume, and other uncontrollable factors. Generally speaking, the production cycle of a carving machine may range from a few weeks to several months. At the same time, the company will also develop reasonable production plans and delivery times based on customer and market demands. Ensuring product quality and delivery time is the core goal of the company's production cycle.

Jibei Economic Development Zone, Jinan City, Shandong Province, China

Tel:+86-138-6266-6677

Email:yang@xkcnc.com

Copyright © 2022 Jinan Xinke CNC Machinery Co., Ltd.

Comment

(0)